ANX-C/M series burners are suitable for applications that strengthen combustion gas recirculation, improve efficiency, improve temperature uniformity and significantly reduce emissions. ANX-C/M series burners include medium, high speed and ultra high speed flame modes. The combustion chamber is made of refractory burner bricks.

ANX-C/M series burner adopts delayed mixing cup structure to delay the mixing process of air and gas in the combustion chamber, reduce the flame temperature in the combustion chamber, and at the same time, the faster flame outlet speed is a large amount of enwinding smoke in the furnace, effectively reducing the generation of nitrogen oxides.

ANX-C/H gas burner design is suitable for enhanced combustion gas recirculation, improved efficiency, improved temperature uniformity and significantly reduced emissions applications. ANX-C/H gas burner series includes medium, high speed and ultra high speed flame mode combustion chamber materials can be configured according to the conditions of use of different materials, such as refractory burner brick, silicon carbide or heat resistant alloy. The ANX-C/H gas burner can reliably burn any standard clean industrial fuel gas over a wide operating range.

Compared with other burners, SF double-hole burner has a wider air-fuel ratio operating area, lower air excess coefficient, lower energy consumption, and better flame stability.

ASF double-hole plate oxygen-depleted burner can be under-wind combustion to consume excess oxygen in the flue gas and reduce flue gas emissions. It is widely used in ceramic industry kilns and other application scenarios that need to maintain a certain flame shape and rigidity.

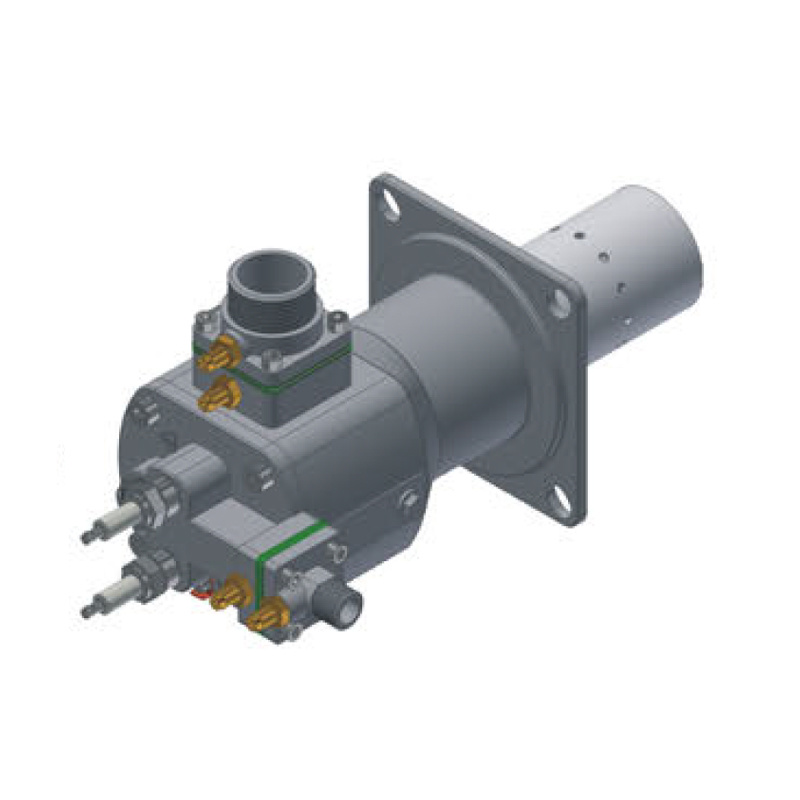

ASR split burner for split assembly, easy to use, simple disassembly, convenient maintenance and high stability. The gun core can be disassembled and assembled separately, and only the gun core needs to be replaced when replacing, and the shell does not need to be removed, which greatly saves manpower, material resources and time. ASR split burner flame stability, high rigidity, can adapt to a variety of complex environment.

The ASD overall burner has high combustion efficiency, blue flame, and various parameters in the combustion products have reached the national environmental protection standards. The power adjustment range is small, the noise is small, no tempering, no fire.

The burner head is made of heat-resistant stainless steel. The burner has automatic ignition and detection functions. It can be matched with the ignition controller to realize automatic temperature control and flameout alarm of the kiln.

The air butterfly valve is used to adjust the combustion capacity at will.

The air butterfly valve is connected with a control motor, which can be automatically controlled.

The gas/air mixture ratio is maintained throughout the combustion process.

The adjustment ratio is relatively high.

Different gas calorific values of 3600 to 30000Kcal/m3 can be used, and the specifications of the nozzles are also different).

Heating method: direct heating, combustion air normally open.

Ignition/detection mode: single electrode ignition detection.

Installation method: movable ferrule type pipe joint connection/fixed flange connection.

Specifications: 4 kinds of power, a variety of burner length optional.

Burner structure: modular design, easy to maintain.

Application: High-power burner ignition/low-power open furnace.

Flame characteristics: the flame is rigid and not easy to be affected by the main burner to cause flameout.

AVP series combined burner uses a mechanical proportional adjustment device to achieve stable and clean combustion. The fuel can be natural gas and liquefied petroleum gas, and the load adjustment signal can be three-wire motor valve and 4-20mA. Air gas control devices and ignition and detection devices are all adopted by the state.

International well-known brand products.

AVP series combined burner uses a mechanical proportional adjustment device to achieve stable and clean combustion. The fuel can be natural gas and liquefied petroleum gas, and the load adjustment signal can be three-wire motor valve and 4-20mA. The air gas control device and ignition, detection device, etc. use international famous brand products.

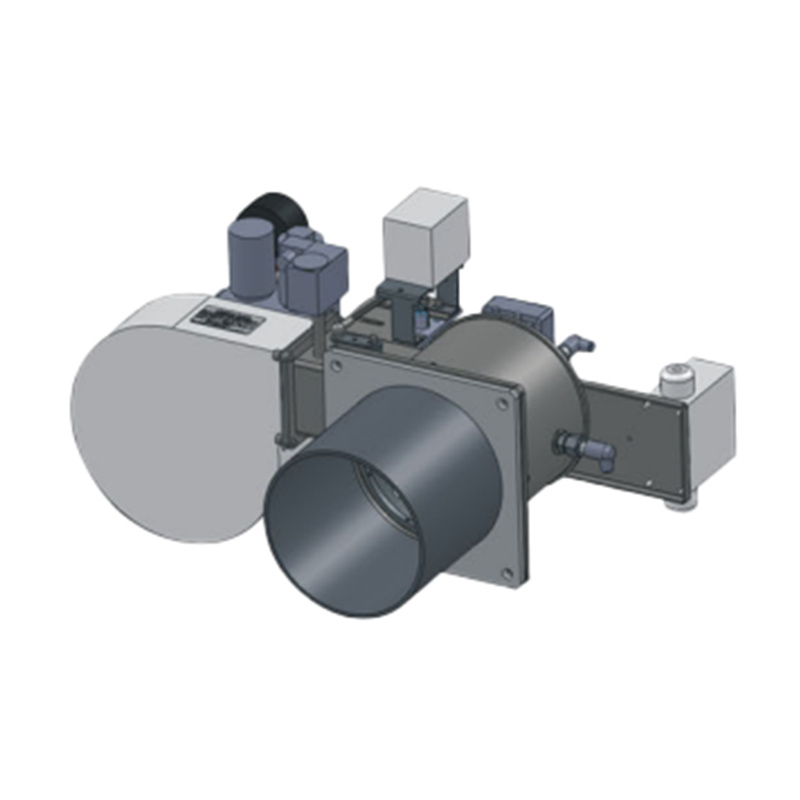

ADZ series low-temperature burner is mainly a product developed for drying equipment with low temperature and large flue gas volume. It can work stably under the conditions of large negative pressure and zero pressure furnace, with large flue gas volume and high temperature. The product adopts double solenoid valve safety protection, wind pressure monitoring, combustion machine controller with purging function and ion bar with flame detection is stable and reliable.

ADZ series low-temperature burner is mainly a product developed for drying equipment with low temperature and large flue gas volume. It can work stably under the conditions of large negative pressure and zero pressure furnace, with large flue gas volume and high temperature. The product adopts double solenoid valve safety protection, wind pressure monitoring, combustion machine controller with purging function and ion bar with flame detection is stable and reliable.

The ACM burner is a linear burner suitable for producing large quantities of clean, high temperature air. This burner is equipped with an integrated combustion air fan, which is installed on the housing of the burner. The blower provides proper air volume and pressure to the burner, so that the burner can operate stably in a wide range of air duct speed, without the need to install a wind deflector around the burner.

The AFD258 controller is an intelligent flame controller with the following features:

Advanced intelligent control chip, intuitive digital tube display, reliable industrial components, strong anti-interference.

External ignition transformer, can be applied to a variety of power intermittent work or continuous work burner control system

Applicable single electrode, double electrode and ultraviolet probe three flame detection methods.

Can detect the flame current signal as low as 1uA, flame detection current threshold value can be set

Flame stabilization time can be set.

The number of key fires can be set.

The controller operating status, fault code and flame signal strength can be displayed.

AFD258 is divided into two versions: one is the basic type and the other is the bus type (Modbus RTU protocol)

Can be used as a slave to communicate with the host computer.

Suitable for all applications that require precise control of 0 ° to 90 · rotational motion. If the power is disconnected, the actuator stops at the current position.

The combined design of actuator AC 20 and control element to adjust the gas volume of various burners and flue gas pipes.

The AC20 actuator and butterfly valve combination is designed to control up to 10:1 gas (including cold and hot air)

The AC20 actuators and linear flow controllers are designed to control up to a 25:1 ratio for gas and cold air. This function is only within the prescribed limits

Chinese

Chinese