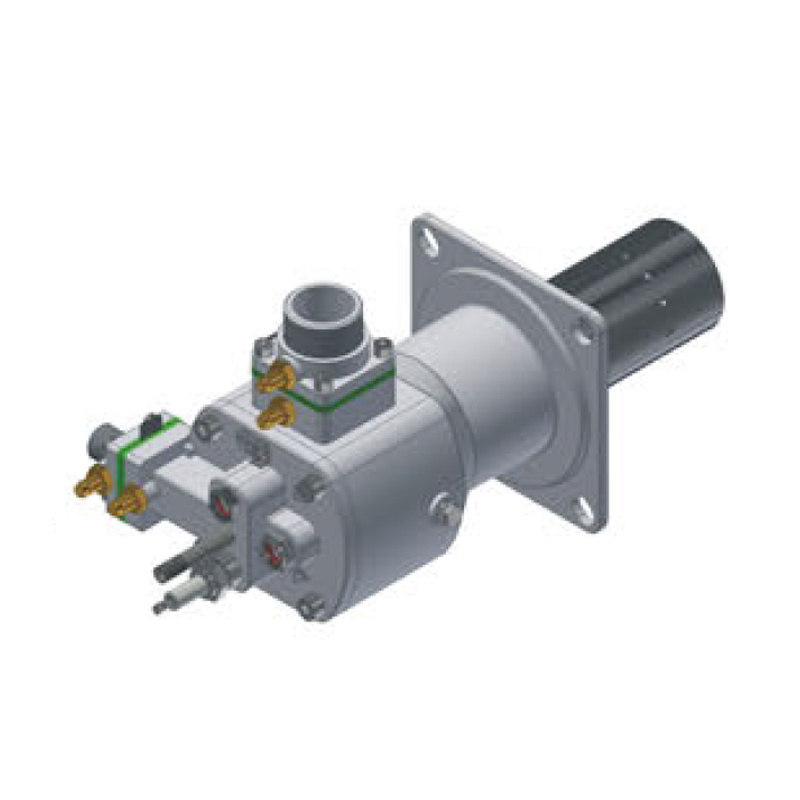

ADJ gas pressure regulator valve with inlet pressure compensation diaphragm and zero closing, which is used to keep the outlet pressure set by the branch pipeline of the gas network constant;

The valve is mainly used to control the gas and air supply pressure of gas burners and gas appliances in the industrial and heating sectors.

Reducing excess air in the kiln is an important way to reduce energy consumption, but maintaining a reasonable working state of hundreds of burners is also the basis for energy saving. Partition regulation can keep the air-fuel ratio of the whole area in a reasonable range, and the regulation of a single burner becomes an almost impossible work on site due to the huge workload.

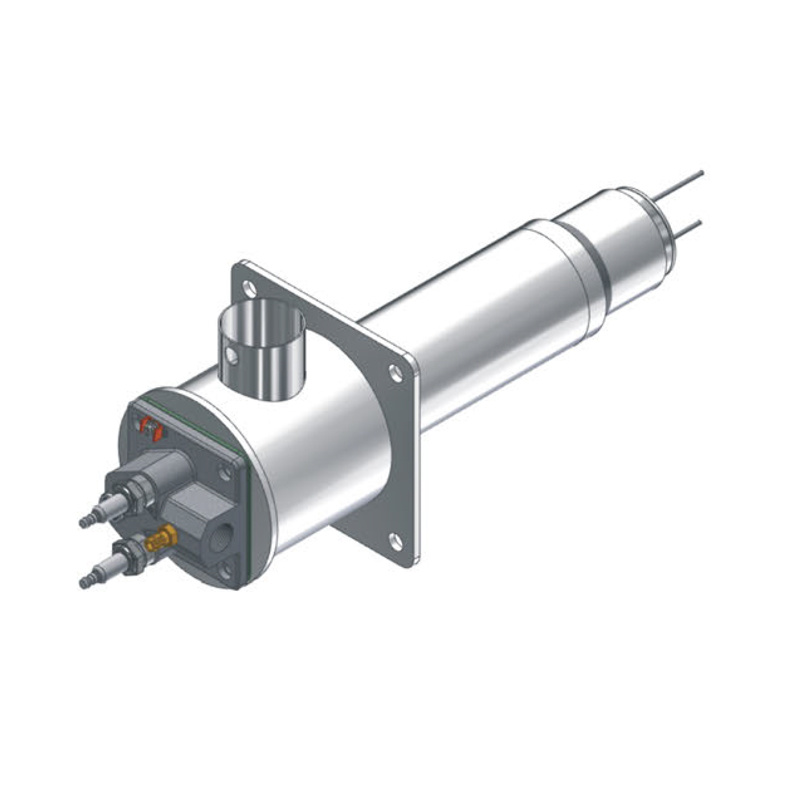

A- UTO automatic adjustment burner for a special burner can automatically control the air-fuel ratio, can ensure that each burner can maintain the best combustion state. The power of the burner is 5-60KW, driven by the gas pressure, and the air-fuel ratio is preset. After that, the burner will automatically match the corresponding air flow according to the gas flow. The maximum service temperature of combustion-supporting air is 250 degrees, the air-fuel ratio can be adjusted, and the minimum opening degree can be adjusted. After the one-time adjustment is completed, it can run automatically.

A- UTO automatic adjustment burner can also be assembled and used together with silicon carbide, and preheated air (below 250C) can be used.

Energy saving Due to the high temperature of the oxygen-enriched combustion flame, the temperature and pressure in the furnace increases, and the radiation heat exchange enhances the effective use of heat in the furnace, thus saving fuel consumption. The adjustment ratio is large, the flame is stable, and the temperature of the fire tube and the nozzle can be effectively controlled to extend the life. Large range of oxygen content

With the increase of oxygen content in oxygen-enriched air, the theoretical air volume decreases, thus changing the combustion characteristics of flame temperature. High flame temperature increases with the increase of oxygen content in oxygen-enriched air. Generally, it is appropriate to control the oxygen content below 28%.

When the oxygen content of oxygen-enriched air increases from 21% to 27%, the heat loss of exhaust gas can be effectively reduced. As the temperature of flue gas increases, the heat of decomposition increases, which is one of the reasons why the oxygen-enriched combustion flame has a large heat transfer capacity.

As the output of modern tunnel kiln and roller kiln is getting bigger and bigger, the kiln body is getting wider and longer, only increasing the burner power and the number of burners on the original kiln body will cause the deterioration of the air flow in the furnace, the imbalance of the pressure control in the furnace, the poor uniformity of the furnace temperature, and the high content of nitrogen oxides in the combustion products, which has great pollution to the environment. The A- IFGR reflux low-nitrogen burner effectively solves the problem of the ceramic burner in the prior art, and provides a reflux ceramic burner, which realizes multi-dimensional three-dimensional circulation of flue gas in the furnace, improves the uniformity of furnace temperature, improves the control of furnace pressure, reduces the flame temperature, inhibits the generation of nitrogen oxides, reduces nitrogen oxide emissions, improves heating quality, and reduces energy consumption.

Industrial furnaces for high temperature heating (above 900°C) and melting applications mostly use gaseous fuels, such as natural gas. When ambient air (especially preheated air) is used as the oxidant, the gaseous flame is usually blue and has a very low luminosity (emissivity), thus reducing the heat exchange between the flame and the furnace contents. In contrast, in many cases, a luminous oil flame is produced, which can reduce fuel consumption by up to 25% and reduce exhaust gas temperature due to its strong heat radiation properties. Therefore, in the case of high temperature heating, the combustion of gaseous fuel to produce a bright flame with high radiation capacity (called glow flame) has important technical and economic value. A- BF flame burner uses a unique patented technology to achieve high thermal emissivity, high brightness reduction flame (or oxidation flame)

1. The formation of plane flame does not depend on aerodynamic design. Therefore, it is not affected by the fluctuation of gas pressure parameters, and the flame will not directly impact the workpiece under any conditions, maintaining stable and efficient radiation heating performance:

2. The flame jet developed by patented technology can design different flame thickness and diameter according to user needs, and better control the directional heat transfer effect of the flame;

3, can make the flat flame burner with high-speed flame performance, has a strong furnace gas suction capacity, promote the uniform distribution of temperature in the furnace;

4, with lower NOx emission levels.

5, effectively avoid the burner slagging fall pollution workpiece, which is particularly important for ceramic products

A- DG burner in NG and LPG two kinds of gas direct switching, operating safety, efficiency, performance and nitride emissions parameters such as no significant change. In actual production, users can choose more favorable fuel from the aspects of gas source stability, fuel quality and fuel price according to the actual conditions; when the conditions change, the fuel can be switched directly without too much change to the control system.

The temperature in modern ultra-high temperature tunnel kiln is as high as 1750-1900C, and the burner should work for a long time in a high temperature environment of about 1000C. Ordinary burners are often used to coke and extinguish the fire and burn the burner head. The ultra-high temperature tunnel kiln burner effectively solves these problems and is an energy-saving product with excellent high temperature performance.

The burner head and fire tube of ultra-high temperature tunnel kiln are made of high temperature resistant and anti-oxidation stainless steel materials, which can work for a long time under high temperature conditions above 1000C without cooling device.

On the basis of the original finned sleeve primary heat exchanger, in order to improve the flue gas waste heat recovery capacity and reduce fuel costs, an auxiliary heat recovery system is added, so that the fuel utilization efficiency is increased to more than 90%, which is close to the level of regenerative heat recovery system, but the structure is simpler, the cost is lower, the occupied space is smaller, and the maintenance performance is better. Therefore, it is more cost-effective than a regenerative burner.

Suitable for natural gas, blast furnace gas, mixed gas, city gas and other fuels combustion flame with direct flame, flat flame and other forms can be installed on the side wall, furnace top and other structures. The material of the heat storage body includes heat storage ball and honeycomb body, which can be ignited by ignition gun and double fire detection mode of ignition gun burner. Widely used in aluminum melting furnace, trolley/chamber heating furnace and heat treatment furnace.

A- RC integrated regenerative burner gets rid of the basic concept of traditional regenerative combustion system-double burner double regenerator structure. Due to the use of unique combustion heat exchange technology, the dual heat storage, combustion, reversing system integration into one, become an independent work, highly integrated, high-tech, epoch-making regenerative burner.

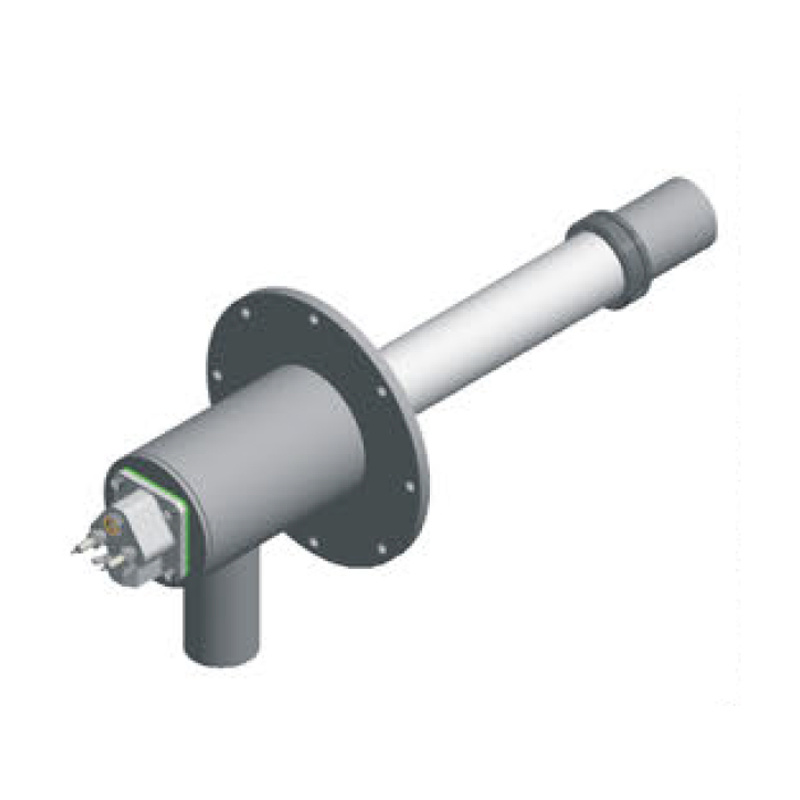

A- GCWR radiant tube burner is specially designed for U-shaped or W-shaped radiant tube scenes to provide low nitrogen emission and uniform temperature flame. Adjust the exhaust position of the smoke to adjust the length of the flame, supporting the use of efficient heat exchanger to play the effect of heat recovery.

A- GCWR radiant tube burner has a certain flame adjustment ability can be used with a variety of different specifications of the radiant tube. A- GCWR radiant tube burner adopts multi-stage air sub-zone combustion technology to greatly reduce NOx emissions.

The flame length can reach five meters, and the temperature is more uniform; efficient preheating recovery, when the furnace temperature is 950C, the exhaust gas temperature can be reduced to 450C, more energy-saving flue gas circulation, lower emissions;

The heat exchanger can choose the shape structure, suitable for a variety of heat treatment furnace; Optional rated power is 90KW and 180KW;

A- HMF high momentum and low nitrogen burner can adapt to the working conditions under high speed, large load and open flame conditions, and provide flame with ultra-low nitrogen emission, high speed, large stirring capacity and furnace gas circulation rate.

The high-speed jet leaves the burner at a higher velocity, optimizing convective heat transfer. A- HMF high momentum low nitrogen burner adopts advanced aerodynamic flame stabilization technology, which can ensure flame stability and reliable ignition under serious deviation from theoretical air volume and low furnace temperature. A- HMF high momentum low nitrogen burner adopts multi-stage air, gas classification and sub-zone combustion technology to greatly reduce NOx emissions.

The A- EGR-HMF burner series is a nozzle hybrid burner that uses multiple bean-ink air nozzles that allow the combustion of high excess air. The special gas jet design produces a high momentum flame. Even if the air is excessive, very stable combustion can be obtained. Adequate homogenization of heating due to the strong stirring of the furnace gas caused by the high momentum flame in the furnace

A- EGR-HMF burner ultra-stable pneumatic flame stabilization technology, allowing the use of excess air combustion, the output of low-temperature flame, can make the furnace temperature control to a lower degree.

A- D-MC dual-mode burner series adopts ultra-high speed and low nitrogen mode (flame jet speed 180 m/s) at low temperature, and switches to MIDL combustion mode at high temperature. At NOX1300 °C furnace temperature, 100mg/m3(@ 8 ,@ 1300 C)A-D-MC dual-mode burner series ultra-high speed main flame is used in low temperature mode. In this mode, staged combustion and ERG effect of high-speed flame can effectively suppress NOx generation. When the furnace temperature exceeds 800 ° C, the system automatically switches to MIDL mode.

Chinese

Chinese