AKR hot air butterfly valve is mainly used for hot air and pipeline flue gas control. It is mainly used for burners (840 degrees Fahrenheit) operated with preheated combustion air at temperatures up to 450°C. It can also be used for manual control, as well as the company's AT31, AT50 and optional Siemens, Hocode | C20 and other foreign actuators or electromagnetic pulse actuators to achieve automatic control.

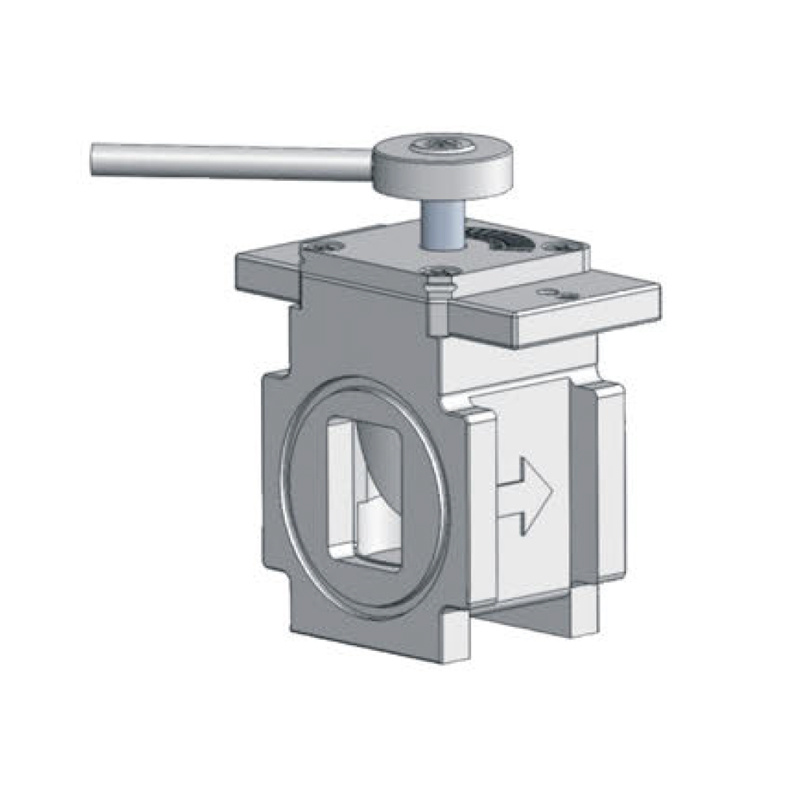

AKL gas/cold air butterfly valve is used in the flow control pipeline system of gas, cold air (≤ 80 ℃) and other low-temperature gases (≤ 150 ℃). It is an ideal equipment for regulating flow in gas pipelines. It has the characteristics of low leakage rate, low pressure loss and high control accuracy. They can be applied to manual control, but also with the company's controller AT31, AT50 and optional Siemens, Hocode and other foreign actuators to achieve automatic control.

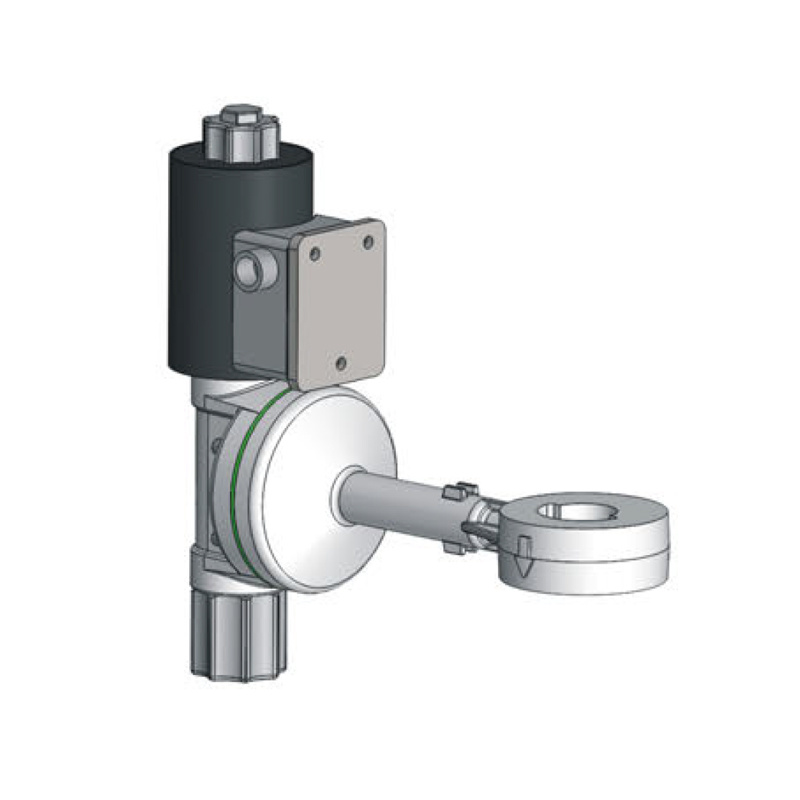

ACK air pulse solenoid butterfly valve is suitable for gas, hot and cold air, and flue gas and other gases. It is an ideal device to adjust the flow in the gas pipeline. Among them, the butterfly valve used by ACK has a safe closing function. In some important occasions, when the main valve is closed and fails, this butterfly valve can also prevent the air from entering the furnace without control.

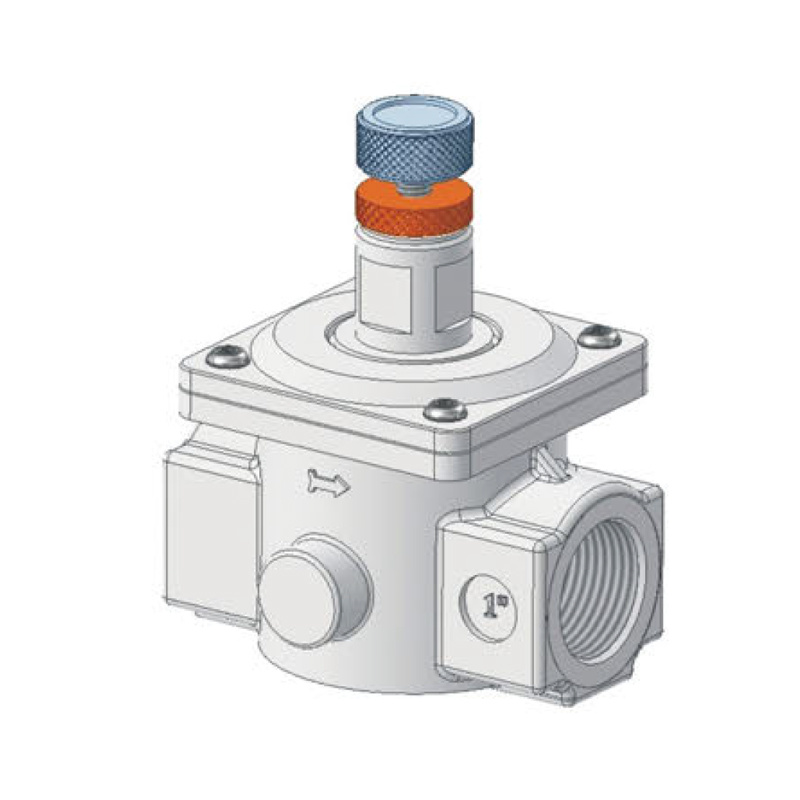

ASH series gas fine adjustment valve is a valve that controls the flow of gas by rotating the knob to control the up and down movement of the valve core inside the valve body to realize the adjustment of the opening size of the valve port;

Widely used in metallurgical industry, textile industry, printing industry of gas heat setting and glass, light bulb industry furnace heating and other industries of gas heating automatic control system.

The AFX flanged linear valve uses the rotary valve principle to set the required flow rate by controlling the rotation angle of the restriction cylinder. The gas flow can be limited in a wide range by the restriction cylinder. This allows optimum use adjustment of the required gas flow without limiting the control accuracy.

Linear flow control valve AFC is used to adjust the flow of combustion and cold air on various equipment, and its adjustment control ratio is 25:1. Equipped with the company's AT31, AT50 and other actuators, suitable for remote adjustment of flow or stage control of the combustion process.

AV E.N series quick-opening and quick-closing gas solenoid valve; AV E.L series slow-opening and fast-closing gas solenoid valve: both series are widely used in the field of safe transportation control to provide opening and closing or cut off gas supply;

The solenoid valve is suitable for gas medium, such as: natural gas, methane, liquefied petroleum gas and other kinds of gas for heating combustion medium pipeline to do two-position on-off power change;

Widely used in metallurgical industry, textile industry, printing industry of gas heat setting and glass, light bulb industry furnace heating and other industries of gas heating automatic control system.

AM R.N series quick-opening and quick-closing gas solenoid valve; AM R.L series slow-opening and fast-closing gas solenoid valve; Both series are widely used in the field of safe transportation control to provide opening and closing or cut off gas supply;

The solenoid valve is suitable for city gas, wave fossil oil and gas, natural gas and other kinds of gas to heat the combustion medium pipeline to do two-position on-off power change, automatic temperature control;

Widely used in metallurgical industry, textile industry, printing industry of gas heat setting and glass, light bulb industry furnace heating and other industries of gas heating automatic control system.

The release valve is used to alleviate the short-term pressure fluctuation in the control system, so as to prevent the accidental activation of the shut-off valve; when the pressure of the control point exceeds the set value due to some temporary reasons, a certain amount of gas is discharged.

AGK air-fuel proportional valve is to achieve a constant gas and air ratio of a valve, used for continuous control or pulse control of gas flow regulation. It can be used for gas pipe network control in metal, glass and ceramic industries, as well as commercial heating, such as packaging, paper and food industries.

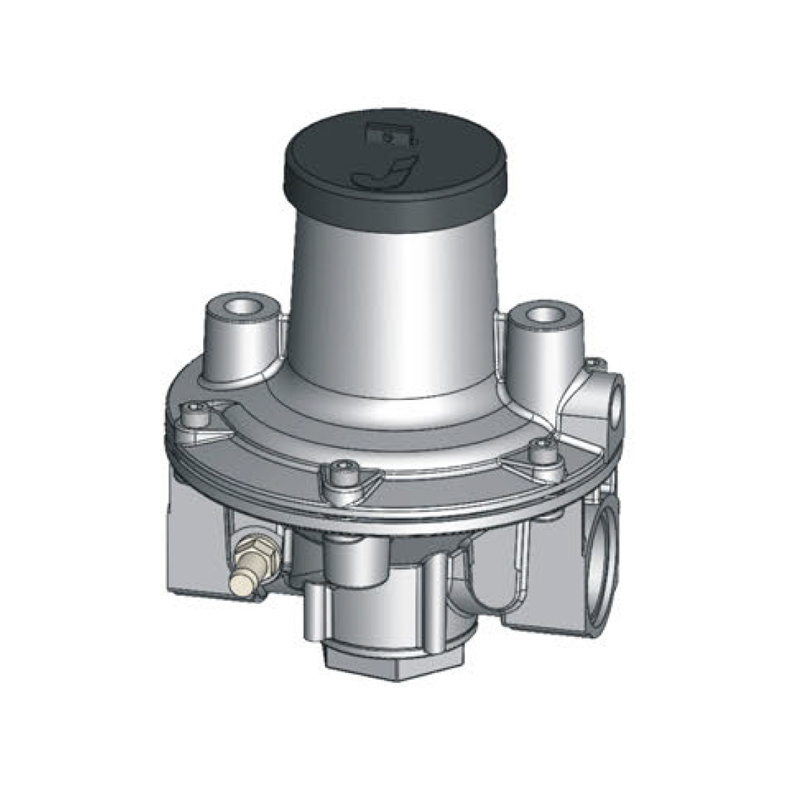

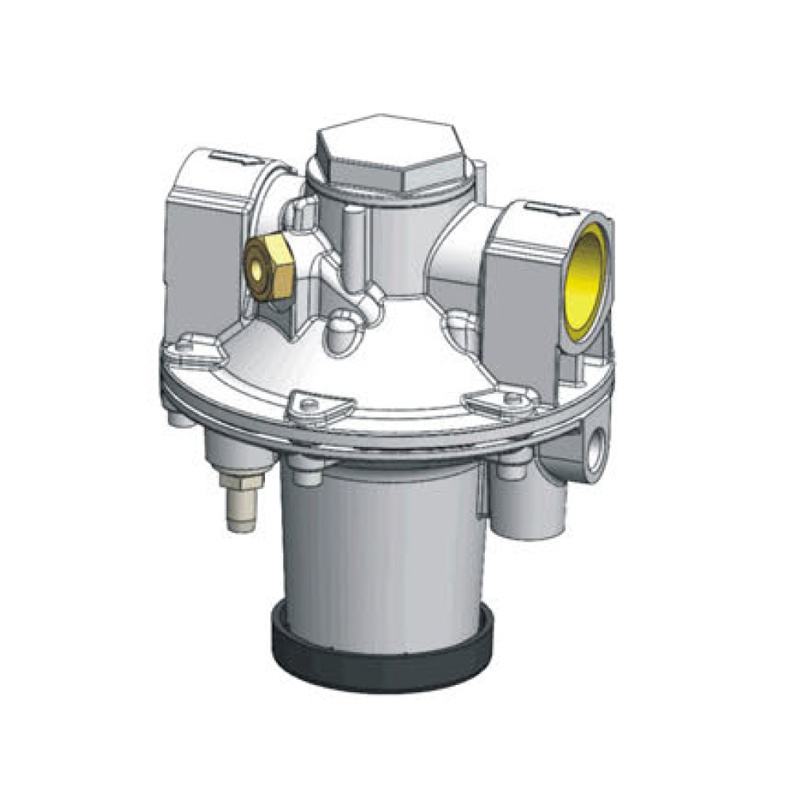

The AGV pressure reducing valve uses the opening of the opening and closing parts in the control valve body to adjust the flow of gas and reduce the pressure of the gas. At the same time, the opening of the opening and closing parts is adjusted by the action of the pressure behind the valve to keep the pressure behind the valve within a certain range.

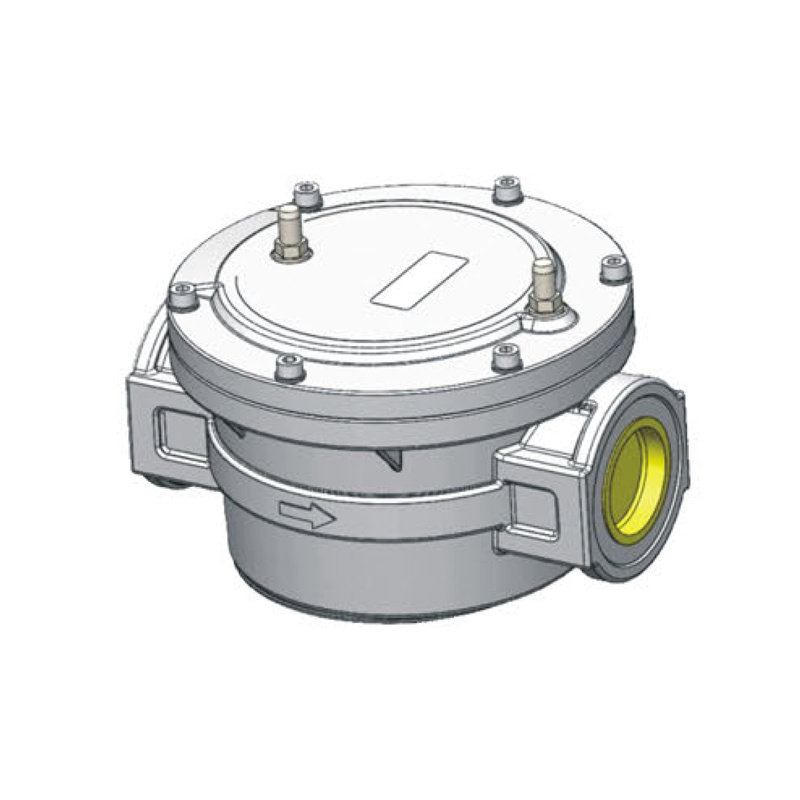

The filter AF is used to be installed upstream on the gas main road to filter the welding slag, iron filings, dust and other impurities brought by the gas medium to protect the downstream equipment, improve the safety performance of the downstream safety equipment, and effectively extend the service life of the downstream equipment.

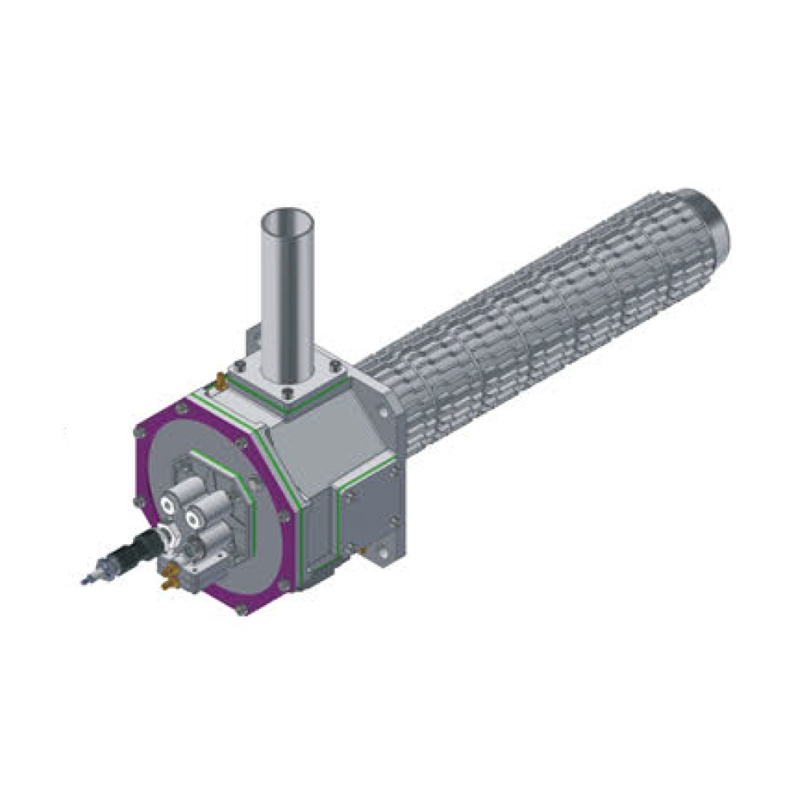

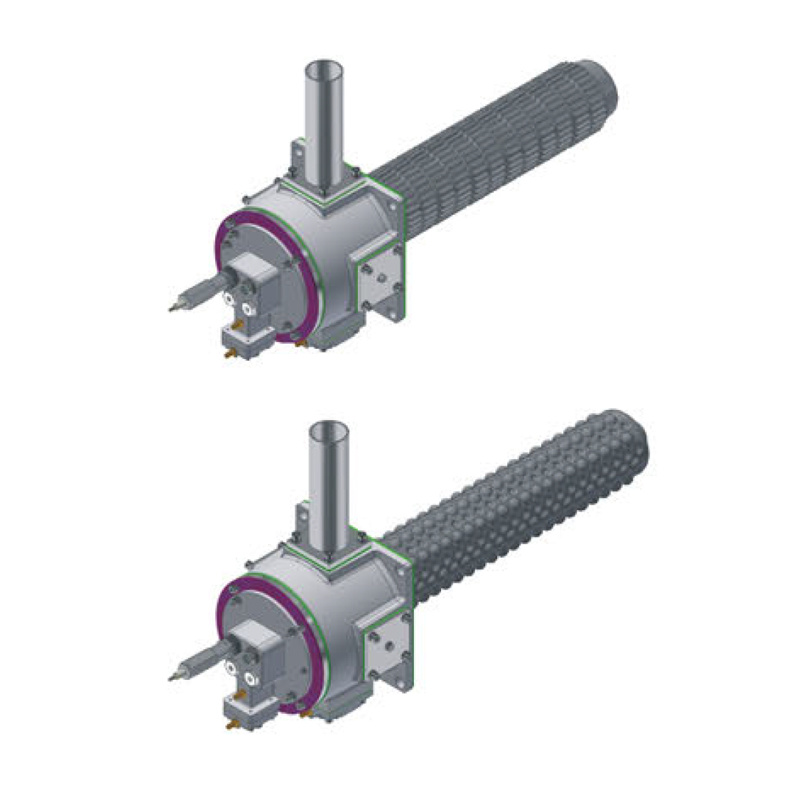

Self-contained heat exchanger to recover waste heat, combustion air can be preheated up to 650C modular design, each module can be replaced and maintained separately. Suitable for pulse control and continuous control. Staged combustion, combustion is more environmentally friendly. The electrode is provided with a cooling air protection circuit and has both detection and ignition functions. Heat-resistant steel heat exchanger, suitable for 950C following a variety of heat treatment furnace type.

The burner is integrated with the heat exchanger, saving the cost of external accessories. High efficiency heat exchange, compared with the traditional regular burner, lower energy consumption. The air staged combustion design is adopted inside the burner to reduce NOx production. The high-speed high-temperature flue gas will play the role of flue gas reflux and stirring in the furnace, so that the temperature distribution in the furnace is uniform. The flue gas generated in the furnace can be discharged through the exhaust system of the burner itself, and the furnace does not need to be equipped with an additional exhaust system. The workpiece can be directly heated by open flame or indirectly heated by radiant tube, and the use occasion is wide.

The structure of the furnace body is simplified, and the spacious combustion chamber of the ordinary heating furnace is no longer needed except the fire channel. The high-speed high-temperature flue gas can eject a large number of lower temperature flue gas in the furnace, forming a strong flue gas reflux and stirring effect, so that the temperature distribution in the furnace is uniform. The adjustment ratio is large, and the convection heat transfer is the main method, so that the temperature in the furnace can be high, low and the thermal inertia is small, and the use range of the furnace is expanded.

Heating method: direct heating, combustion air normally open.

Ignition/detection mode: single electrode ignition detection.

Installation method: flange connection.

Burners structure: modular design, easy to maintain

Application: regenerative burner ignition/low power open furnace

Flame characteristics: strong flame rigidity, not easy to be affected by the main burner caused by flameout

Chinese

Chinese